Injection Tooling Services

Custom injection mold tooling in YCX-mold is necessary to validate and refine designs, reduce costs, and accelerate the product development process by accommodating unique features and allowing for rapid iterations.

Tight Tolerance of 0.02 mm

Professional DFM Report

Free Mold Flow Analysis

Start Get A Quote

All drawings are secure and confidential.

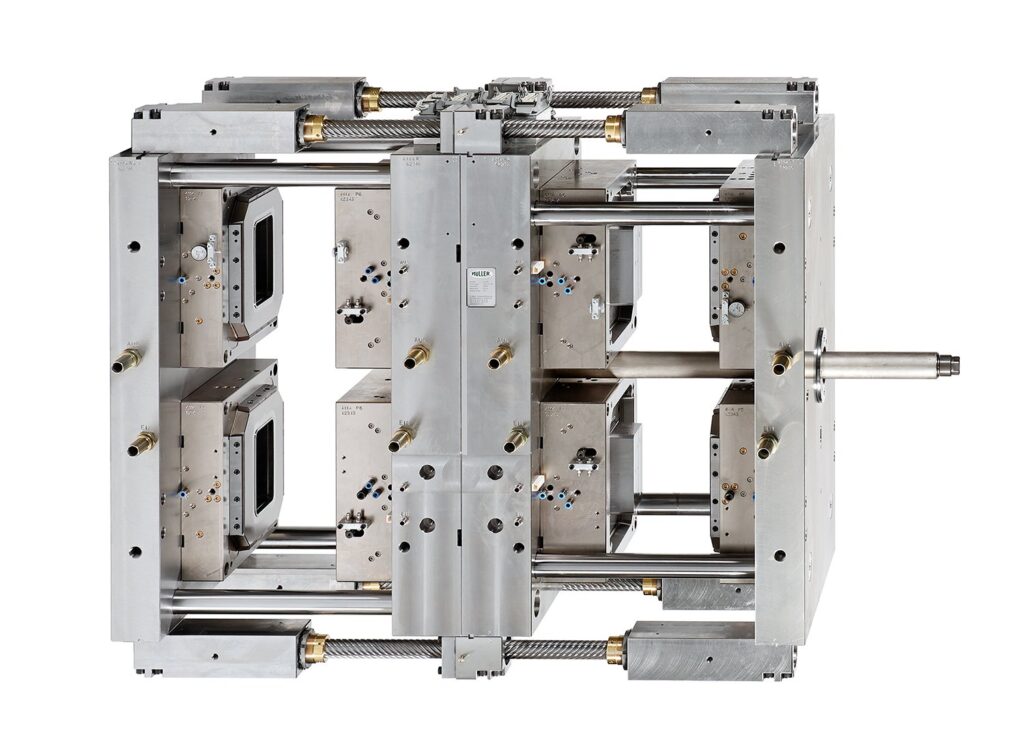

Types of Injection Mold Tooling

Single Cavity Mold

Multi Cavity Mold

Stack Mold

2K Injection Mold

Injection Mold Tooling Capabilities

All surfaces will have a consistent visual appearance.

Parts will have the support structures removed and will be cleaned of all excess support/build material.

Mold Class

Purpose

Shot Life

Tolerance

Cost

Lead Time

Class 105

Prototype Testing

Under 500 cycles

± 0.02mm

$

7-10 days

Class 104

Low-volume Production

Under 100.000 cycles

± 0.02mm

$$$

10-15 days

Class 103

Low-volume Production

Under 500.000 cycles

± 0.02mm

$$$$

10-15 days

Class 102

Medium-volume Production

Under 1,000,000 cycles

± 0.02mm

$$$$$

10-15 days

Class 101

Medium-volume Production

Over 1,000,000 cycles

± 0.02mm

$$$$$

10-18 days

Injection Mold Tooling Materials

Material name

Subtypes

Price

Delivery period

Characteristics

Tool Steel

P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

$$$$$

10-15 days

Tool steel is a high-hardness, wear-resistant material

Stainless Steel

420, NAK80, S136, 316L, 316, 301, 303, 304

$$$$$

10-15 days

Stainless steel is a corrosion-resistant alloy known for its durability, high tensile strength

Aluminum

6061, 5052, 7075

$$$$$

7-10 days

Aluminum is a lightweight, corrosion-resistant, malleable metal

Injection Molding Surface Finishes

SPI surface finishes

We offer any type of SPI surface finish, such as A-1, D-2 or D-3.

VDI surface finishes

We offer any type of VDI surface finish, such as VDI28, VDI30 or VDI 33.

Our Customers speak for us