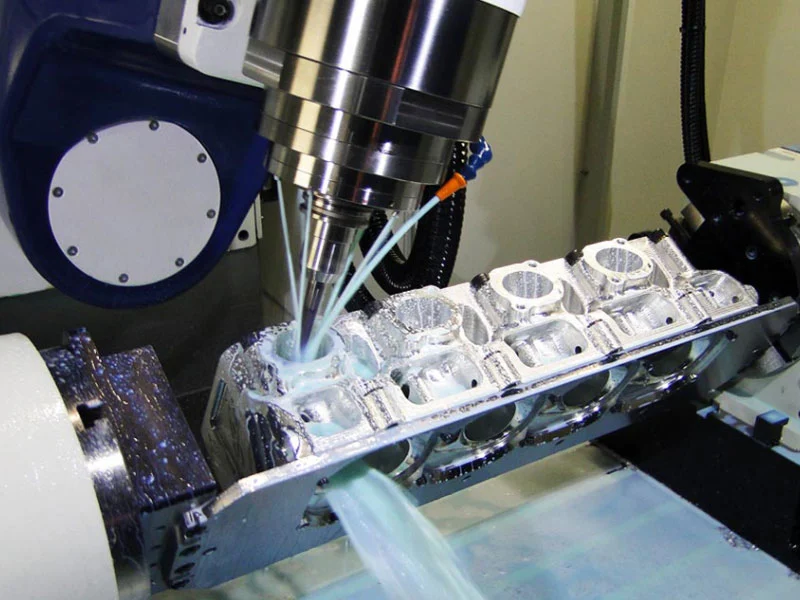

Have you ever wondered how make those machine corridor? They surely didn't make them with their hands or cast them in a furnace. They make these crafted corridor from a process called CNC perfection machining. Still, CNC perfection machining is a process that uses computer programs to produce products with exact specifications, If you ’re new to the manufacturing world. In this composition, we ’ll define the process, the outfit used, their operations, and the programming and processing involved. As a leading manufacturing and machining Manufacturer in China, YCX plant breaks down all the details below, starting with the basics.

What's CNC Precision Machining?

Still, then’s the answer, If the question “ What's precise machining? ” still lingers in your mind. Just as the name implies, perfection machining involves shaping raw material into a finished product by cutting out surpluses as designated by a CAD or CAM design. What’s more, machinists use this process in different manufacturing processes and on different accoutrements .

What are the tolerance of CNC perfection machining?

Before making any product, using CAD or CAM programs to make the product’s design is necessary. That's to say, these programs make largely detailed 3D outlines that a precise machining process must follow to replicate the product successfully. From toys to medical bias, motorcars, or space shuttles, any product that has corridor needs perfection machining. Using CNC outfit, the process utilizes conduct like cutting, mulling, turning, and electrical discharge machining to achieve the final product. Although the process requires the overwatch of a professed machinist, a machine does utmost of the work automatically. The CAD software creates the design, and the CAM software also translates it into manufacturing instructions for the machine. A finalpost-processor software canons the instruction into information the machine can understand. The machinists also load the instruction into the CNC outfit to start the manufacturing process. There are different types of tolerance dimension systems.

1 、 Unilateral tolerance dimension In this type of tolerance dimension, the divagation is only allowed on one side of the nominal value. This means if the nominal value of a shaft to fit into a bearing is 20 mm, a shaft larger than this would n’t fit in. thus, machinists only allow the divagation for such a shaft on the lower side.

2 、 Limit tolerance This is when the tolerance value is placed in a range. For illustration, if the nominal value for the shaft is 15 mm and the tolerance is 15 –15.5 mm, this represents a limit tolerance.

3 、 Bilateral tolerance This type of tolerance allows divagation on both sides of the nominal value. It's generally expressed as a/- value. To clarify, if a crafted part has a dimension of 25 mm with a tolerance of/-0.05 mm, it means the value can be within24.95 mm and25.05 mm. Knowing when to choose tighter tolerance for your part manufacturer is veritably important. Although it isn't necessary for the whole part to have tight tolerance, the important structural corridor, similar as those which fit into other factors, need little divagation from the nominal value as trip could oppressively affect the integrity of the part. tolerance are important in precise machining processes because they help to reduce product costs and reversal times. As important as they are, they bear a lot of skill and tolerance to get it right. The standard tolerance of CNC machines is0.005 elevation. At RapidDirect, our 5- axis CNC machines can achieve tolerance up to0.002 ”. We offer a range of tolerance to suit our guests ’ needs. Our standard tolerance for CNC machining essence are biddable with noise-2768-1-fine, while for plastics it's DIN-2768-1-medium.

Please fill the form to let us know your need. Our sales will get in touch with you ASAP.