YONGCHANGXING has a rich experience and expertise in the injection molds field and has a diverse management team and skilled engineers who can meet different needs of global customers.

YONGCHANGXING has a professional and prompt customer support and after-sales service team that can communicate well in different languages and resolve any problems or issues that may occur. It also provides OEM or ODM services for different industries and customer specifications.

YONGCHANGXING has competitive and reasonable prices for its injection molds products and services. It also offers discounts and benefits for large orders and long-term cooperation.

YONGCHANGXING has achieved other international certifications to ensure high quality and standards. It also uses state-of-the-art equipment and technology to ensure high precision and accuracy of its injection molds products. It also conducts product inspection with robotic arms and CMM to detect any defects or errors.

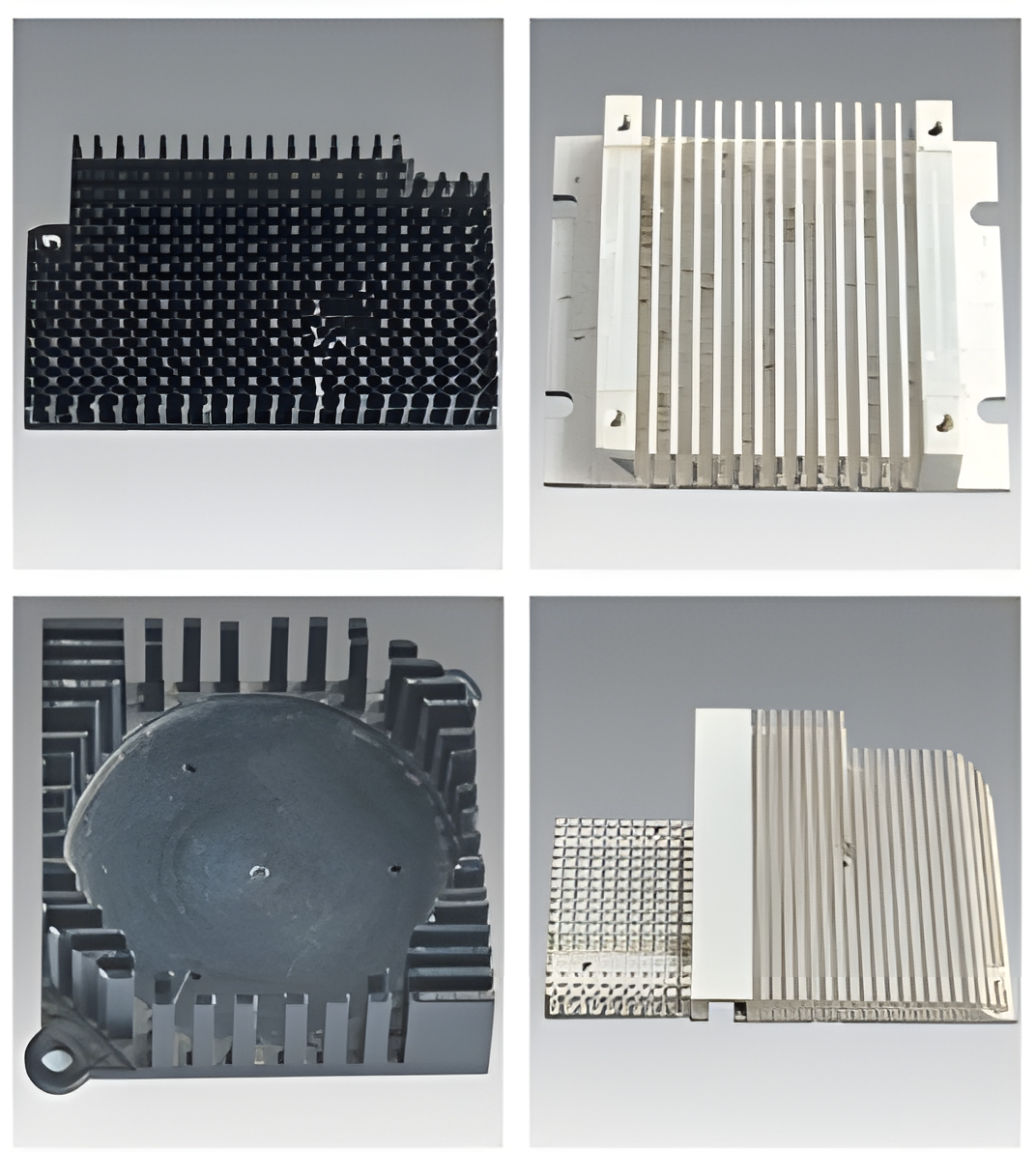

Related Products

More items about die casting mold

We Have The Best Solutions for Your Business

GuangDong YongChangXing Precision Manufacturing Co., Ltd was established in 2002 and went public in 2015 .(stock code number: 833271). YCX is a professional processing company which has the abundant experience in the particular field of mold design and manufacturing, plastic injection molding,hot pressing molding, CNC machining, Die casting, paint spraying, movable printing, silk screen, UV, gold printing and plastic water plating. The covering area of manufacturer is 15800 square meters and the number of employees exceeded 500.

The Challenges and Opportunities of Aluminum Alloy for Mold Die Casting Mold Operations

Aluminum alloy has both challenges and opportunities for mold die casting mold operations because of its high melting point, high thermal conductivity, and high reactivity. Aluminum alloy has a high melting point, which requires a high temperature and pressure for the die casting process, which can increase the energy consumption and cost of the mold operations. Aluminum alloy has a high thermal conductivity, which can cause a rapid heat loss and solidification of the molten metal, which can reduce the fluidity and fillability of the mold cavity. Aluminum alloy has a high reactivity, which can cause oxidation and corrosion of the mold material and equipment, which can affect the durability and maintenance of the mold operations. However, these challenges can also be overcome by using advanced techniques and technologies, such as vacuum die casting, squeeze casting, and hot chamber die casting, which can improve the efficiency and quality of the aluminum alloy die casting mold operations.

Aluminum Alloy: A Cost-Effective and Versatile Material for Hardware Die Casting Mold Products

Aluminum alloy is a cost-effective and versatile material for hardware die casting mold products because of its low cost, high quality, and wide range of applications. Aluminum alloy is cheaper than other metals such as steel or brass, which can lower the material and production cost of the hardware products. Aluminum alloy has higher quality than other metals such as zinc or magnesium, which can improve the performance and reliability of the hardware products. Aluminum alloy die casting mold can produce various types of hardware products for different industries and purposes, such as furniture hardware, door hardware, window hardware, and cabinet

Plastic Mold Design and Optimization with Zinc Alloy Die Casting Mold Technology

Plastic mold design and optimization can be achieved with zinc alloy die casting mold technology because of its high fluidity, low melting point, and fast solidification. Zinc alloy can fill the mold cavity quickly and evenly, which can reduce the defects and errors of the plastic parts. Zinc alloy can also cool down rapidly, which can shorten the cycle time and increase the productivity of the plastic parts. Zinc alloy die casting mold can offer a wide range of design options and flexibility for plastic parts, such as shapes, sizes, colors, and textures.

The Benefits of Zinc Alloy for Car Die Casting Mold Production

Zinc alloy has many benefits for car die casting mold production, such as high hardness, wear resistance, and dimensional stability. Zinc alloy can withstand high temperatures and pressures, which can improve the durability and safety of the car parts. Zinc alloy can also create smooth and aesthetic surfaces, which can enhance the appearance and quality of the car parts. Zinc alloy die casting mold can produce complex and thin-walled parts with high accuracy and efficiency, such as engine components, transmission parts, and chassis parts.

User Reviews

What users say about YONGCHANGXING

Frequently Asked Question

Do you have any question?

Our company’s name is YONGCHANGXING and our main product and service is die casting mold. We can provide you with custom design, engineering, production, and after-sales service for your die casting mold projects.

YONGCHANGXING has been in the die casting mold industry for over 20 years and we have rich experience and expertise in this field. We have a professional team of engineers, designers, technicians, and workers who can handle any die casting mold project, from simple to complex, from small to large.

YONGCHANGXING’s die casting mold has many advantages compared to other suppliers, such as high quality, competitive price, fast delivery, strict quality control, and excellent after-sales service. We use advanced equipment, technology, and materials to ensure the quality and performance of our die casting mold. We also offer flexible and customized solutions to meet your specific needs and requirements.

YONGCHANGXING can provide various types of die casting mold, such as aluminum die casting mold, zinc die casting mold, magnesium die casting mold, etc. Each type of die casting mold has its own features and applications. For example, aluminum die casting mold is lightweight, durable, corrosion-resistant, and suitable for automotive, aerospace, electronic, and other industries. Zinc die casting mold is strong, rigid, precise, and suitable for hardware, furniture, appliance, and other industries. Magnesium die casting mold is lightest, strongest, heat-resistant, and suitable for medical, military, and other industries.