YONGCHANGXING has a rich experience and expertise in the injection molds field and has a diverse management team and skilled engineers who can meet different needs of global customers.

YONGCHANGXING has a professional and prompt customer support and after-sales service team that can communicate well in different languages and resolve any problems or issues that may occur. It also provides OEM or ODM services for different industries and customer specifications.

YONGCHANGXING has competitive and reasonable prices for its injection molds products and services. It also offers discounts and benefits for large orders and long-term cooperation.

YONGCHANGXING has achieved other international certifications to ensure high quality and standards. It also uses state-of-the-art equipment and technology to ensure high precision and accuracy of its injection molds products. It also conducts product inspection with robotic arms and CMM to detect any defects or errors.

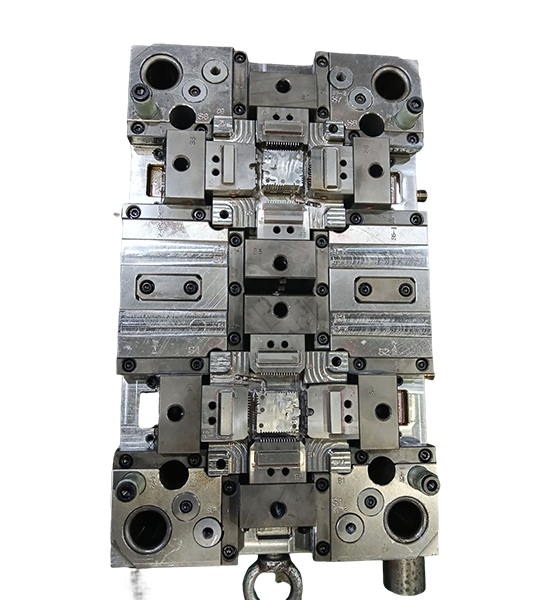

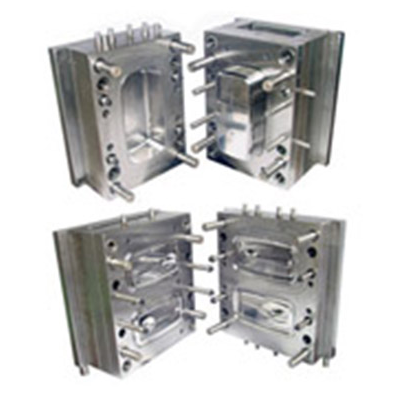

Related Products

More items about motor die

We Have The Best Solutions for Your Business

GuangDong YongChangXing Precision Manufacturing Co., Ltd was established in 2002 and went public in 2015 .(stock code number: 833271). YCX is a professional processing company which has the abundant experience in the particular field of mold design and manufacturing, plastic injection molding,hot pressing molding, CNC machining, Die casting, paint spraying, movable printing, silk screen, UV, gold printing and plastic water plating. The covering area of manufacturer is 15800 square meters and the number of employees exceeded 500.

How to Choose the Right Process for Motor Die Casting

Motor die casting is a process that involves creating motor parts and components using die casting technology. Die casting technology is a method that uses high pressure and high temperature to inject molten metal into a mold. There are different types of die casting processes, such as hot chamber, cold chamber, vacuum, and squeeze. To choose the right process for motor die casting, you need to consider several factors, such as the type, size, shape, and material of the motor parts and components. You also need to consider the cost, speed, quality, and efficiency of the die casting process.

How to Use Induction Motor Die Casting for Energy Saving and Cost Reduction

Induction motor die casting is a process that involves creating induction motor parts and components using die casting technology. Induction motor is a type of motor that uses electromagnetic induction to generate torque. Induction motor die casting can help you save energy and reduce cost in your motor production process by providing high efficiency, durability, and functionality. To use induction motor die casting, you need to use suitable tools and machines to inject molten metal into a mold. You also need to use appropriate cooling, lubrication, and protection methods to prevent overheating, wear, and damage of the induction motor parts and components.

What is Permanent Magnet Motor Die Casting and How to Improve Its Quality and Efficiency

Permanent magnet motor die casting is a process that involves creating permanent magnet motor parts and components using die casting technology. Permanent magnet motor is a type of motor that uses permanent magnets to generate magnetic fields. Permanent magnet motor die casting can improve the quality and efficiency of permanent magnet motor parts and components by providing high accuracy, precision, and functionality. To improve permanent magnet motor die casting, you need to use advanced technology, quality materials, and strict quality control. You also need to optimize the design, simulation, testing, and evaluation of permanent magnet motor die casting.

The Benefits and Challenges of Electric Motor Die Casting

Electric motor die casting is a process that involves creating electric motor parts and components using die casting technology. Electric motor is a type of motor that converts electrical energy into mechanical energy. Electric motor die casting has many benefits and challenges for various applications and industries. Some of the benefits are reducing the weight, size, and cost of the electric motor, improving the performance, durability, and appearance of the electric motor, and allowing customization and innovation. Some of the challenges are meeting the high standards and regulations of the electric motor industry, ensuring the quality and accuracy of the electric motor parts and components, and preventing overheating, wear, and damage of the electric motor parts and components.

User Reviews

What users say about YONGCHANGXING

Frequently Asked Question

Do you have any question?

We communicate and cooperate with our customers during the die casting mold project by using various methods and channels. We assign a project manager and a project team to each customer to keep them updated on the project progress and status. We also use email, phone call, online chat, video conference, etc. to communicate with our customers in a timely and effective manner. We also welcome our customers to visit our factory or send their representatives to inspect our die casting mold.

We train and develop our staff for our die casting mold production by providing them with various training programs and opportunities. We have a systematic training system that covers the basic knowledge, skills, and attitudes of our staff. We also have a regular training schedule that updates and refreshes our staff’s knowledge and skills. We also encourage our staff to participate in external training courses, seminars, workshops, etc. to enhance their professional development.

We handle the feedback and complaints from our customers about our die casting mold by listening to them carefully and respectfully. We take every feedback and complaint seriously and try our best to solve them as soon as possible. We also follow up with our customers to make sure they are satisfied with our solutions. We also learn from our feedback and complaints to improve our quality and service.