Features

Why Choose YONGCHANGXING?

YONGCHANGXING has a rich experience and expertise in the injection molds field and has a diverse management team and skilled engineers who can meet different needs of global customers.

YONGCHANGXING has a professional and prompt customer support and after-sales service team that can communicate well in different languages and resolve any problems or issues that may occur. It also provides OEM or ODM services for different industries and customer specifications.

YONGCHANGXING has competitive and reasonable prices for its injection molds products and services. It also offers discounts and benefits for large orders and long-term cooperation.

YONGCHANGXING has achieved other international certifications to ensure high quality and standards. It also uses state-of-the-art equipment and technology to ensure high precision and accuracy of its injection molds products. It also conducts product inspection with robotic arms and CMM to detect any defects or errors.

We Have The Best Solutions for Your Business

GuangDong YongChangXing Precision Manufacturing Co., Ltd was established in 2002 and went public in 2015 .(stock code number: 833271). YCX is a professional processing company which has the abundant experience in the particular field of mold design and manufacturing, plastic injection molding,hot pressing molding, CNC machining, Die casting, paint spraying, movable printing, silk screen, UV, gold printing and plastic water plating. The covering area of manufacturer is 15800 square meters and the number of employees exceeded 500.

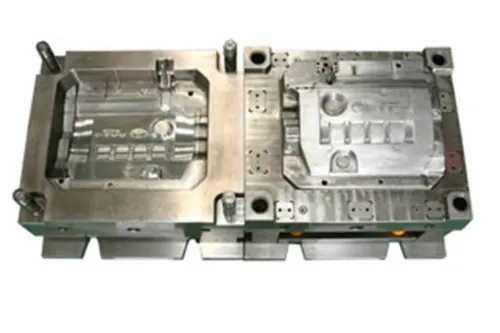

Injection Molding: A Metal Casting Process for Producing Plastic Parts. Injection molding is a metal casting process that uses high pressure to force molten plastic into reusable metal molds. Injection molding can produce accurate, smooth, and uniform parts in large quantities. Injection molding has many advantages, such as high quality, low cost, fast production, and less waste. Injection molding can be used for various industries and applications, such as automotive, aerospace, electronic, medical, military, hardware, furniture, appliance, lighting, etc. Injection molding can produce different types of plastic parts, such as engine parts, gearbox parts, chassis parts, brake parts, steering parts, etc.

Injection Molding Process: The injection molding process consists of four main stages: clamping, injection, cooling, and ejection. The two halves of the metal mold (the cavity and the core) are clamped together by a hydraulic or mechanical device. The plastic resin is fed into a heated barrel where it is melted into a liquid state. A screw or a plunger pushes the molten plastic through a nozzle into the mold cavity. The amount of plastic injected into the mold is called the shot. The molten plastic inside the mold cavity begins to cool and solidify as it contacts the cold surface of the mold. The cooling time depends on the thickness and shape of the part, as well as the type of plastic resin used. After the plastic part is fully cooled and solidified, the mold opens and the part is ejected by a mechanism such as ejector pins or air blast. The part may require further trimming or finishing to remove excess material or defects.

Injection Molding Materials: Injection molding can be performed with a host of materials mainly including metals (for which the process is called die-casting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Materials can be combined to deliver different properties and effects for the finished parts. Some of the common materials used for injection molding are:

Acrylic (PMMA): Acrylic is a transparent and rigid material that has good optical properties and resistance to weathering and UV radiation. Acrylic is used for products such as keyboard keys, protective headgear, electrical outlet wall plates, etc.

Acrylonitrile Butadiene Styrene (ABS): ABS is a tough and impact-resistant material that has good mechanical properties and dimensional stability. ABS is used for products such as automotive parts like wheel covers, consumer goods, sports equipment, industrial fittings, etc.

Nylon Polyamide (PA): Nylon is a strong and flexible material that has good abrasion resistance and thermal stability. Nylon is used for products such as strong mechanical parts such as bearings, bushings

Featured Products

Collection about YONGCHANGXING

User Reviews

What users say about YONGCHANGXING

Frequently Asked Question

Do you have any question?

YONGCHANGXING ensures the quality and reliability of our die casting mold by following strict quality control procedures throughout the whole process. We conduct material inspection, design review, mold flow analysis, sample testing, production inspection, final inspection, and packaging inspection before delivery. We also have ISO 9001 certification and comply with international standards and regulations.

YONGCHANGXING handles the delivery and shipment of our die casting mold by using reliable and professional logistics partners. We can arrange the shipment by sea, air, or land according to your preference and convenience. We can also provide you with the tracking number and the documents for your die casting mold. We will deliver your die casting mold to you on time and in good condition.

YONGCHANGXING deals with the after-sales service and warranty of our die casting mold by providing you with prompt and satisfactory service. We offer a one-year warranty for our die casting mold and we will repair or replace any defective parts for free within the warranty period. We also provide technical support and guidance for your die casting mold usage and maintenance. If you have any questions or problems with our die casting mold, please feel free to contact us anytime.

YONGCHANGXING protects the intellectual property rights of our customers by signing a non-disclosure agreement (NDA) with them before starting any cooperation. We respect and keep confidential all the information and data that our customers provide us. We do not disclose or use any of their information or data without their permission. We also do not copy or sell any of their designs or products to others.

Our updates and blog posts

What Materials and Fields Can Use Metal Injection Molding?

MIM (metal injection molding) is a process of injecting a mix of metal powder and binder into a mold. The powder and binder are blended, granulated, and then molded into the desired shape.

What is Metal Injection Molding? 5 Facts to Learn

How metal injection molding works: injecting powder metal into a mold to form small and complex products.

What are the 4 Main Steps of the Metal Injection Molding Process?

The basics of metal injection molding in 4 stages