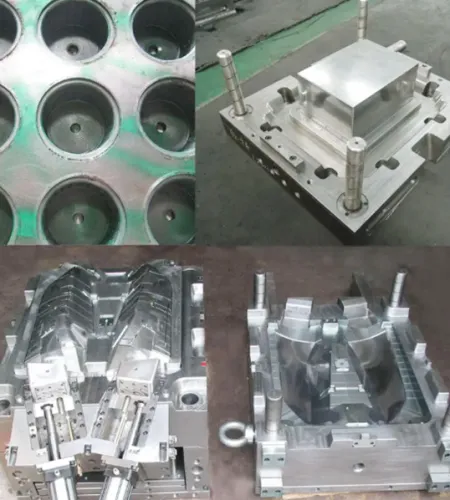

YONGCHANGXING has a rich experience and expertise in the injection molds field and has a diverse management team and skilled engineers who can meet different needs of global customers.

YONGCHANGXING has a professional and prompt customer support and after-sales service team that can communicate well in different languages and resolve any problems or issues that may occur. It also provides OEM or ODM services for different industries and customer specifications.

YONGCHANGXING has competitive and reasonable prices for its injection molds products and services. It also offers discounts and benefits for large orders and long-term cooperation.

YONGCHANGXING has achieved other international certifications to ensure high quality and standards. It also uses state-of-the-art equipment and technology to ensure high precision and accuracy of its injection molds products. It also conducts product inspection with robotic arms and CMM to detect any defects or errors.

Related Products

More items about stamping die

We Have The Best Solutions for Your Business

GuangDong YongChangXing Precision Manufacturing Co., Ltd was established in 2002 and went public in 2015 .(stock code number: 833271). YCX is a professional processing company which has the abundant experience in the particular field of mold design and manufacturing, plastic injection molding,hot pressing molding, CNC machining, Die casting, paint spraying, movable printing, silk screen, UV, gold printing and plastic water plating. The covering area of manufacturer is 15800 square meters and the number of employees exceeded 500.

How to Find a Reliable Ironing Stamping Die ODM for Smoothing the Wall Thickness of Metal Parts

Ironing stamping die ODM is a company that designs and manufactures ironing stamping dies for customers according to their specifications. Ironing stamping dies are metal stamping dies that smooth the wall thickness of metal parts. To find a reliable ironing stamping die ODM, you need to do some research, such as checking their portfolio, contacting their references, visiting their factory, and comparing their quotes. Checking their portfolio means that you look at their previous projects and samples of their ironing stamping dies. Contacting their references means that you ask their previous or current customers about their experience and satisfaction with their ironing stamping dies. Visiting their factory means that you inspect their facilities and equipment and observe their production process. Comparing their quotes means that you evaluate their prices and terms and conditions for their ironing stamping dies.

How Extrusion Stamping Die Forms Long and Thin Metal Parts

Extrusion stamping die is a process that forms long and thin metal parts by pushing metal through a hole or a slit. The shape and size of the hole or the slit determines the cross-section of the metal parts. For example, a round hole can form a rod, a small hole can form a wire, a hollow hole can form a tube, and a long slit can form a strip. Extrusion stamping die can also create different shapes and sizes of metal parts by changing the hole or the slit.

How Flanging Stamping Die Adds Strength and Stability to Metal Parts

Flanging stamping die is a process that uses a metal stamping die to bend the edges of metal parts. Flanging stamping die can add strength and stability to metal parts in various ways, such as increasing rigidity, reducing vibration, preventing buckling, and enhancing connection. Flanging stamping die can increase rigidity by creating a stiff edge that resists bending. Flanging stamping die can reduce vibration by creating a smooth edge that absorbs noise. Flanging stamping die can prevent buckling by creating a curved edge that distributes stress. Flanging stamping die can enhance connection by creating a flange that can be fastened or welded to another part.

How Lancing Stamping Die Creates Slots and Tabs for Metal Parts

Lancing stamping die is a process that creates slots and tabs for metal parts by cutting and bending metal without separating it from the metal sheet. The slots and tabs can serve different purposes and functions, such as vents, hinges, locks, and connectors. For example, a vent can allow air flow by creating slits, a hinge can allow movement by creating strips, a lock can allow attachment by creating hooks, and a connector can allow connection by creating pins. Lancing stamping die can also create different shapes and sizes of slots and tabs by changing the cut and the bend.

User Reviews

What users say about YONGCHANGXING

Frequently Asked Question

Do you have any question?

The main industries and applications that YONGCHANGXING serves for our die casting mold are automotive, aerospace, electronic, medical, military, hardware, furniture, appliance, lighting, etc. We can provide you with various types of die casting mold for different products and parts, such as engine parts, gearbox parts, chassis parts, brake parts, steering parts, etc.

The main advantages and benefits of using die casting mold for your products and parts are as follows: 1) Die casting mold can produce complex and precise shapes with high dimensional accuracy and surface quality; 2) Die casting mold can reduce the material waste and production cost by eliminating or minimizing the need for machining and finishing; 3) Die casting mold can improve the mechanical properties and performance of your products and parts by enhancing their strength, durability, and resistance; 4) Die casting mold can increase the production efficiency and capacity by enabling mass production and automation.

We ensure the safety and environmental protection of our die casting mold production by following the relevant laws and regulations and adopting the best practices. We have a strict safety management system and a professional safety team to monitor and control the potential risks and hazards. We also have a comprehensive environmental management system and a dedicated environmental team to reduce the environmental impact and pollution. We use eco-friendly materials and processes to minimize the waste generation and energy consumption.