YONGCHANGXING has a rich experience and expertise in the injection molds field and has a diverse management team and skilled engineers who can meet different needs of global customers.

YONGCHANGXING has a professional and prompt customer support and after-sales service team that can communicate well in different languages and resolve any problems or issues that may occur. It also provides OEM or ODM services for different industries and customer specifications.

YONGCHANGXING has competitive and reasonable prices for its injection molds products and services. It also offers discounts and benefits for large orders and long-term cooperation.

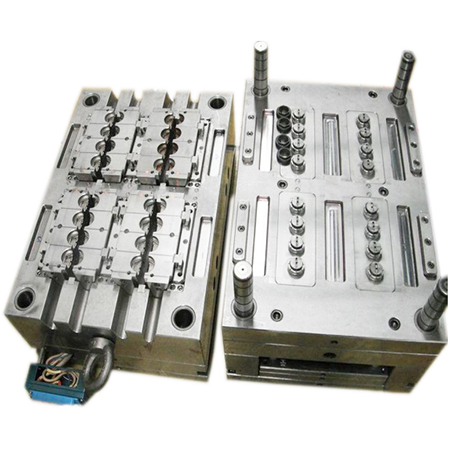

YONGCHANGXING has achieved other international certifications to ensure high quality and standards. It also uses state-of-the-art equipment and technology to ensure high precision and accuracy of its injection molds products. It also conducts product inspection with robotic arms and CMM to detect any defects or errors.

Related Products

More items about injection molds

We Have The Best Solutions for Your Business

GuangDong YongChangXing Precision Manufacturing Co., Ltd was established in 2002 and went public in 2015 .(stock code number: 833271). YCX is a professional processing company which has the abundant experience in the particular field of mold design and manufacturing, plastic injection molding,hot pressing molding, CNC machining, Die casting, paint spraying, movable printing, silk screen, UV, gold printing and plastic water plating. The covering area of manufacturer is 15800 square meters and the number of employees exceeded 500.

Injection Molds Cost: What Factors Affect the Cost of Injection Molds?

Injection molds cost is one of the most important factors that affect your decision when choosing an injection molds supplier. However, injection molds cost is not a fixed number that can be easily calculated. It depends on many factors that vary from project to project. Some of these factors are mold material, mold design, production quantity, quality and performance requirements.

Injection Molds Process: How Does Injection Molding Work?

Injection molding is a metal casting process that uses high pressure to force molten plastic into metal molds. Injection molding can produce accurate, smooth, and uniform parts in large quantities. Injection molding has many advantages, such as high quality, low cost, fast production, and less waste. Injection molding can be used for various industries and applications. The injection molding process consists of four stages: clamping, injection, cooling, and ejection.

Injection Molds Quality: How to Ensure the Quality and Reliability of Injection Molds?

Injection molds quality is one of the most critical factors that affect the success of your injection molds project. You need to ensure that your injection molds are designed and produced with high quality and reliability, so that they can produce high-quality and reliable plastic parts. There are several ways to ensure the quality and reliability of injection molds, such as quality control procedures, testing equipment and instruments, data and feedback collection.

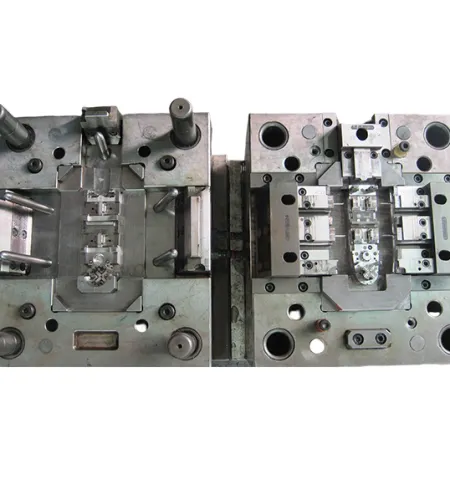

Injection Molds Types: What Are the Different Types of Injection Molds?

Injection molds are metal molds that produce plastic parts by injecting molten plastic. Injection molds can be classified into different types according to different criteria. Some of these types are single-cavity or multi-cavity, hot runner or cold runner, stripper plate or ejector pin. Each type has its own advantages and disadvantages, and can be selected according to the specific needs of the project.

User Reviews

What users say about YONGCHANGXING

Frequently Asked Question

Do you have any question?

YONGCHANGXING calculates the price of our die casting mold based on several factors, such as mold material, mold design, mold size, mold complexity, production quantity, delivery time, etc. We will send you a quotation after receiving your detailed requirements and specifications for your die casting mold. We will also offer you some discounts if you place a large order or a long-term cooperation with us.

The main equipment and technology that YONGCHANGXING uses for our die casting mold production are CNC machining centers, EDM machines, wire cutting machines, drilling machines, milling machines, grinding machines, polishing machines, etc. We also use CAD/CAM/CAE software, mold flow analysis software, and 3D printing technology to design and optimize our die casting mold.

You can start a cooperation with YONGCHANGXING by contacting us via email, phone call or online chat. You can also visit our website or factory to learn more about us. You can send us your inquiry or request for your die casting mold project. We will reply you within 24 hours and provide you with a professional and satisfactory service. We look forward to working with you.