YONGCHANGXING has a rich experience and expertise in the injection molds field and has a diverse management team and skilled engineers who can meet different needs of global customers.

YONGCHANGXING has a professional and prompt customer support and after-sales service team that can communicate well in different languages and resolve any problems or issues that may occur. It also provides OEM or ODM services for different industries and customer specifications.

YONGCHANGXING has competitive and reasonable prices for its injection molds products and services. It also offers discounts and benefits for large orders and long-term cooperation.

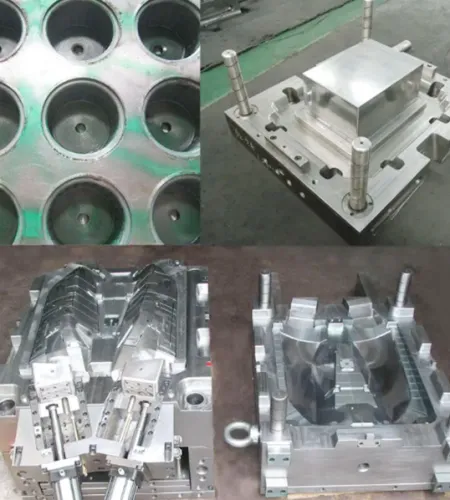

YONGCHANGXING has achieved other international certifications to ensure high quality and standards. It also uses state-of-the-art equipment and technology to ensure high precision and accuracy of its injection molds products. It also conducts product inspection with robotic arms and CMM to detect any defects or errors.

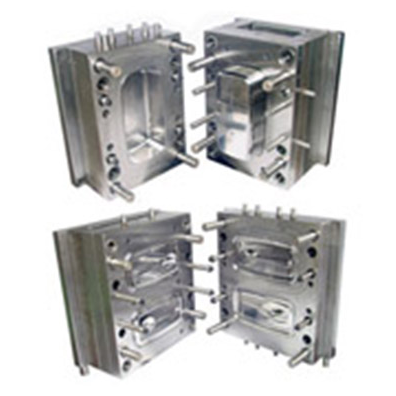

Related Products

More items about injection molding

We Have The Best Solutions for Your Business

GuangDong YongChangXing Precision Manufacturing Co., Ltd was established in 2002 and went public in 2015 .(stock code number: 833271). YCX is a professional processing company which has the abundant experience in the particular field of mold design and manufacturing, plastic injection molding,hot pressing molding, CNC machining, Die casting, paint spraying, movable printing, silk screen, UV, gold printing and plastic water plating. The covering area of manufacturer is 15800 square meters and the number of employees exceeded 500.

The Advantages and Applications of Rotary Table Injection Molding Manufacturer.

Rotary table injection molding is a metal casting process that uses a rotating table to insert multiple cores or cavities into a single mold. Rotary table injection molding has many advantages, such as increasing the productivity and efficiency, reducing the cycle time

How to Find a Reliable Fiber-Filled Plastic Injection Molding Manufacturer.

Fiber-filled plastic injection molding can produce plastic parts with increased stiffness, strength, and durability. To find a reliable manufacturer, you should check their experience, reputation, capabilities, equipment, communication, and service. You should also ask for references and samples to verify their quality and performance.

How to Choose the Right Reinforced Plastic Injection Molding Supplier for Your Project.

Reinforced plastic injection molding can produce plastic parts with enhanced properties and performance. However, choosing the right supplier for your project is crucial for your success. You should consider some criteria, such as experience, reputation, capabilities, equipment, communication, service, quality, delivery time, and price. You should also evaluate their samples and feedback from previous customers.

How to Get the Best Price for Reinforced Plastic Injection Molding Parts.

Reinforced plastic injection molding can produce plastic parts with enhanced properties and performance. However, the price of reinforced plastic injection molding parts depends on several factors, such as material cost, mold cost, production cost, and quality requirements. To get the best price, you should compare different suppliers, negotiate the terms and conditions, optimize the design and process, and reduce the waste and defects.

User Reviews

What users say about YONGCHANGXING

Frequently Asked Question

Do you have any question?

YONGCHANGXING ensures the quality and reliability of our die casting mold by following strict quality control procedures throughout the whole process. We conduct material inspection, design review, mold flow analysis, sample testing, production inspection, final inspection, and packaging inspection before delivery. We also have ISO 9001 certification and comply with international standards and regulations.

YONGCHANGXING handles the delivery and shipment of our die casting mold by using reliable and professional logistics partners. We can arrange the shipment by sea, air, or land according to your preference and convenience. We can also provide you with the tracking number and the documents for your die casting mold. We will deliver your die casting mold to you on time and in good condition.

YONGCHANGXING deals with the after-sales service and warranty of our die casting mold by providing you with prompt and satisfactory service. We offer a one-year warranty for our die casting mold and we will repair or replace any defective parts for free within the warranty period. We also provide technical support and guidance for your die casting mold usage and maintenance. If you have any questions or problems with our die casting mold, please feel free to contact us anytime.

YONGCHANGXING protects the intellectual property rights of our customers by signing a non-disclosure agreement (NDA) with them before starting any cooperation. We respect and keep confidential all the information and data that our customers provide us. We do not disclose or use any of their information or data without their permission. We also do not copy or sell any of their designs or products to others.