Features

Why Choose YONGCHANGXING?

YONGCHANGXING has a rich experience and expertise in the injection molds field and has a diverse management team and skilled engineers who can meet different needs of global customers.

YONGCHANGXING has a professional and prompt customer support and after-sales service team that can communicate well in different languages and resolve any problems or issues that may occur. It also provides OEM or ODM services for different industries and customer specifications.

YONGCHANGXING has competitive and reasonable prices for its injection molds products and services. It also offers discounts and benefits for large orders and long-term cooperation.

YONGCHANGXING has achieved other international certifications to ensure high quality and standards. It also uses state-of-the-art equipment and technology to ensure high precision and accuracy of its injection molds products. It also conducts product inspection with robotic arms and CMM to detect any defects or errors.

We Have The Best Solutions for Your Business

GuangDong YongChangXing Precision Manufacturing Co., Ltd was established in 2002 and went public in 2015 .(stock code number: 833271). YCX is a professional processing company which has the abundant experience in the particular field of mold design and manufacturing, plastic injection molding,hot pressing molding, CNC machining, Die casting, paint spraying, movable printing, silk screen, UV, gold printing and plastic water plating. The covering area of manufacturer is 15800 square meters and the number of employees exceeded 500.

YONGCHANGXING: Your Trusted Partner for Insert Molding Services

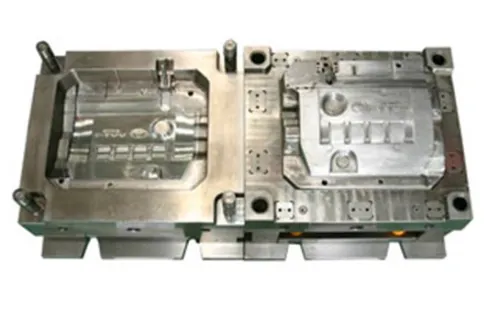

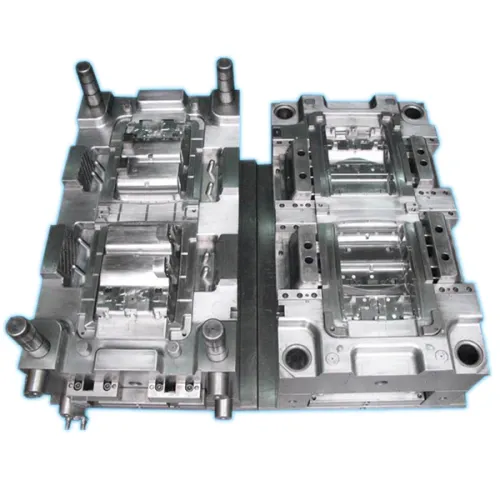

Insert molding is a process that combines metal and plastic parts into a single component. Insert molding involves placing metal inserts into a mold cavity and injecting plastic around them, forming a single component with a strong bond. Insert molding can improve the strength, performance, and aesthetics of your products. Insert molding can also reduce the cost and time of your project by eliminating the need for assembly or fastening. Insert molding can be used for various applications and industries, such as automotive, medical, electronics, and aerospace.

YONGCHANGXING is a leading provider of insert molding services in China. We have over 20 years of experience in plastic injection molding and metal insert molding. We have the expertise and equipment to handle your insert molding needs, from design to production. We can work with various materials, such as stainless steel, brass, aluminum, copper, and plastic. We can also produce complex and customized parts with high accuracy and quality. We have a strict quality control system and a professional engineering team to ensure your satisfaction. We offer competitive prices and fast delivery times for your insert molding projects.

If you are looking for a reliable and experienced insert molding partner, look no further than YONGCHANGXING. We are ready to assist you with your insert molding needs and provide you with the best solutions. Contact us today to get a free quote and consultation. We look forward to hearing from you.

Featured Products

Collection about YONGCHANGXING

User Reviews

What users say about YONGCHANGXING

Frequently Asked Question

Do you have any question?

We ensure the continuous improvement and innovation of our die casting mold by investing in research and development (R&D) activities. We have a strong R&D team that consists of experienced engineers, designers, technicians, researchers, etc. They are constantly exploring new materials, technologies, methods, etc. to improve and innovate our die casting mold. We also cooperate with universities, research institutes, industry associations, etc. to exchange ideas and information.

We train and develop our staff for our die casting mold production by providing them with various training programs and opportunities. We have a systematic training system that covers the basic knowledge, skills, and attitudes of our staff. We also have a regular training schedule that updates and refreshes our staff’s knowledge and skills. We also encourage our staff to participate in external training courses, seminars, workshops, etc. to enhance their professional development.

The main equipment and technology that YONGCHANGXING uses for our die casting mold production are CNC machining centers, EDM machines, wire cutting machines, drilling machines, milling machines, grinding machines, polishing machines, etc. We also use CAD/CAM/CAE software, mold flow analysis software, and 3D printing technology to design and optimize our die casting mold.

Our updates and blog posts

What Materials and Fields Can Use Metal Injection Molding?

MIM (metal injection molding) is a process of injecting a mix of metal powder and binder into a mold. The powder and binder are blended, granulated, and then molded into the desired shape.

What is Metal Injection Molding? 5 Facts to Learn

How metal injection molding works: injecting powder metal into a mold to form small and complex products.

What are the 4 Main Steps of the Metal Injection Molding Process?

The basics of metal injection molding in 4 stages